-

3D printers

Back

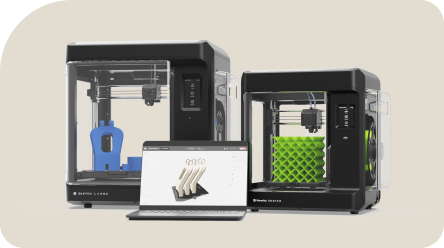

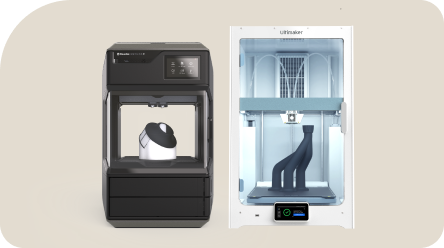

3D printers

Upgrade your classroom with reliable 3D printers used across 10,000+ schools.

Meet the new Sprint -

Education

Back

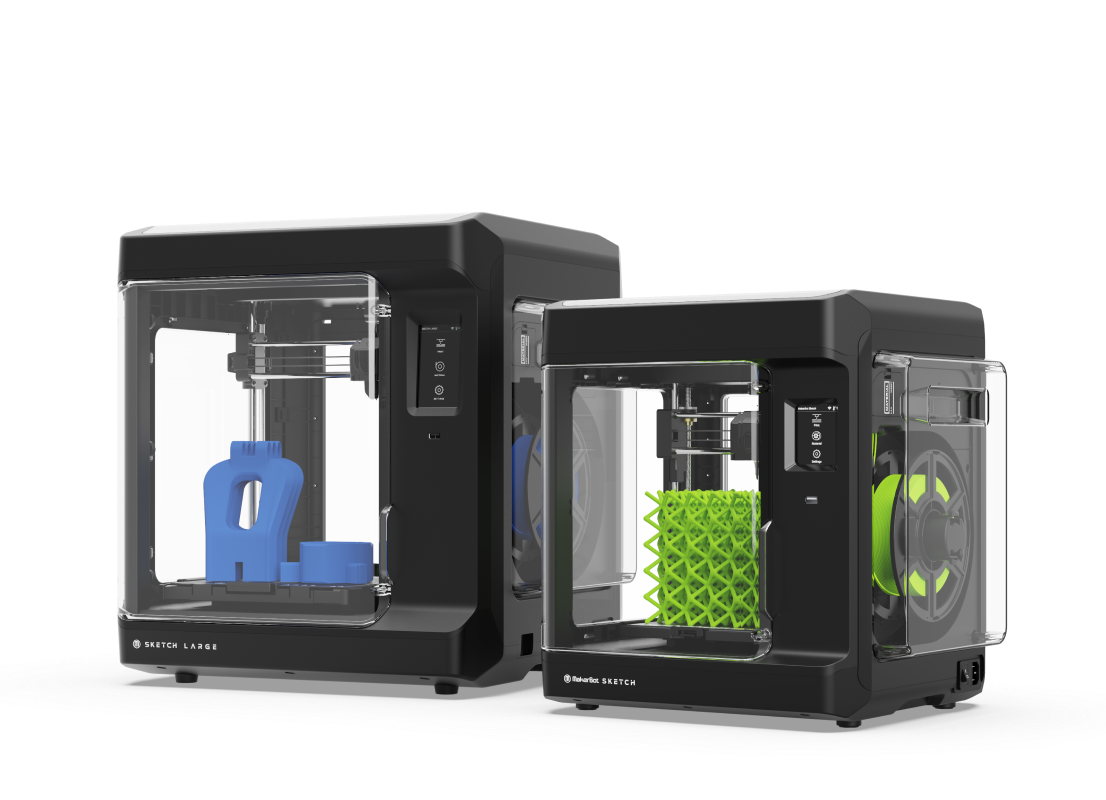

Sketch Classroom Solution

3D printing in the classroom isn’t just about the 3D printer. It’s about the curriculum, the projects, and knowledge that surrounds it. Explore all the solutions that MakerBot has available for you

Classroom setup -

Software

Back

-

Training

Back

Training

Tailored certifications that will help you and your students become experts in 3D printing.

Explore certification -

Resources

Back

Resources

Free access to hundreds of 3D printing lesson plans to help teach a range of subjects.

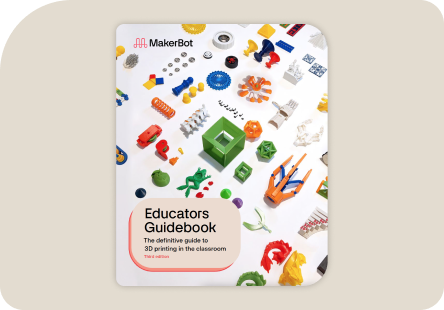

Browse all blogs and webinarsMakerBot Educator’s Guidebook

Updated for 2023, this guide has become a 3D printing textbook for students and educators.

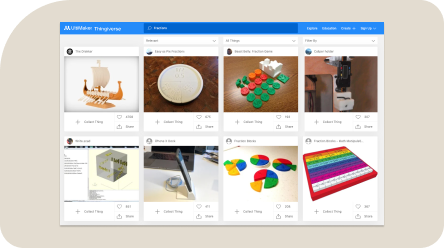

Thingiverse Education Community

Browse hundreds of 3D printing ideas that help engage students of any subject.

Webinars, lessons, blogs, and more

Get tips and tricks on how to use 3D printing to bring your curriculum to life.

-

Support

Back

Support

Visit our support site for setup videos, how-to guides, FAQs, and technical expertise from our support team.

Support site