1980s

The earliest 3D printing technologies came about in the 1980s. They were called Rapid Prototyping (RP) technologies because they were first conceived as a faster and more cost-effective means of creating prototypes for product development within the industry.

The first patent application for RP technology was filed in 1980, by Dr. Hideo Kodama of the Nagoya Municipal Industrial Research Institute in Japan. It described a rapid prototyping system using photopolymers. A solid, printed model was built up in layers, with each layer corresponding to a cross-sectional slice of the model. Unfortunately for Dr. Kodama, he failed to follow up on his patent application and never commercialized his printing process.

1984

Charles Hull made 3D printing history when he invented stereolithography, a process which allowed designers to create 3D models using digital data, which is then used to create a physical object.

The key to stereolithography is an acrylic-based material called a photopolymer. A vat of liquid photopolymer is exposed to a UV laser beam with the light-exposed portion instantly turning into a solid piece of plastic, molded to the shape of the 3D model design.

This was big news for inventors, who could now prototype and test designs without needing to make a huge upfront investment in manufacturing processes.

1986

Charles Hull created the first stereolithographic apparatus (SLA) machine. This 3D printing technique made it possible to print complex parts, layer by layer, in a fraction of the time it would normally take. Charles Hull went on to found 3D Systems Corporation, which introduced the world’s first commercial 3D printing system, the SLA-1.

1987

Carl Deckard at the University of Texas, pioneered an alternative method of 3D printing called the Selective Laser Sintering (SLS) RP process. It used a laser to turn loose powder into a solid. It was not until 2006 that SLS machines became commercially viable, which created new opportunities in manufacturing.

1989

Scott Crump, with his wife and fellow inventor, Lisa Crump, invented and patented a new 3D printing method called Fused Deposition Modeling (FDM). The method involved melting a polymer filament and depositing it onto a substrate, layer by layer, to create a 3D object.

The idea for the technology occurred to Crump a year earlier, when he tried to create a toy frog for his daughter using a hot glue gun filled with a mixture of polyethylene and candle wax. As he struggled to do it manually, he saw a way to automate the process by building the shape from a series of layers stacked on top of each other.

Crump went on to found Stratasys, Inc., one of the most prominent additive manufacturing companies in the world today; the company still holds the patent for their proprietary FDM technology.

1999

The use of 3D printed organs in surgery became a reality when a lab-grown urinary bladder was successfully transplanted into a patient, using technology developed by the Wake Forest Institute for Regenerative Medicine.

The artificial bladder was created by taking a CT scan of the patient’s bladder and then printing a biodegradable scaffold using the information from the scan. Cells grown from a tissue sample taken from the patient were layered onto the scaffold before the transplant, with little to no chance of the patient’s immune system rejecting the regenerated tissue, as it was made from its own cells.

1999-2010

was a profound decade for 3D printing in medicine. During this 10-year period, scientists from various institutions and startups fabricated a functional miniature kidney, built a prosthetic leg with complex parts printed within the same structure, and bioprinted the first blood vessels using only human cells.

The decade also marked the intersection of 3D printing and the open-source movement. In

2004

, Dr. Adrian Bowyer, a senior lecturer in mechanical engineering at the University of Bath in the U.K., founded the RepRap project. It was an open-source project which aimed to build a 3D printer that could print most of its own parts.

The idea behind it was to democratize 3D printing by making the technology available to people around the world – friends could print 3D printers for their friends.

The first RepRap printer, named “Darwin” was released in

2007

, followed by later versions called “Mendel,” “Prusa Mendel,” and “Huxley.” All were named after famous evolutionary biologists because the project was all about replication and evolution.

Shapeways, a 3D printing service in the Netherlands, launched in

2008

, bringing 3D printing to a wider audience. Instead of giving people their own 3D printers, Shapeways had users submit their own files which the company printed and shipped back.

Shapeways rapidly expanded to Queens, in New York City and made 3D printing accessible to the non-tech population, including artists, architects, and other creatives.

In 2009

, Kickstarter launched. The crowdfunding site quickly became a huge money-raising platform for a large number of 3D printers. Some crashed and burned, others became major players in the printing industry. The most funded Kickstarter 3D printer project was Micro, in

2014

, featured as the first truly consumer 3D printer. Its creators had asked for $50,000 and instead raised a staggering $3,401,361.

Also in

2009

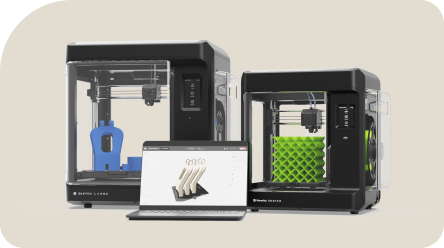

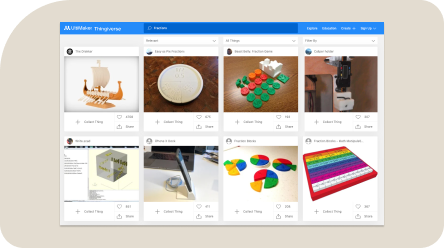

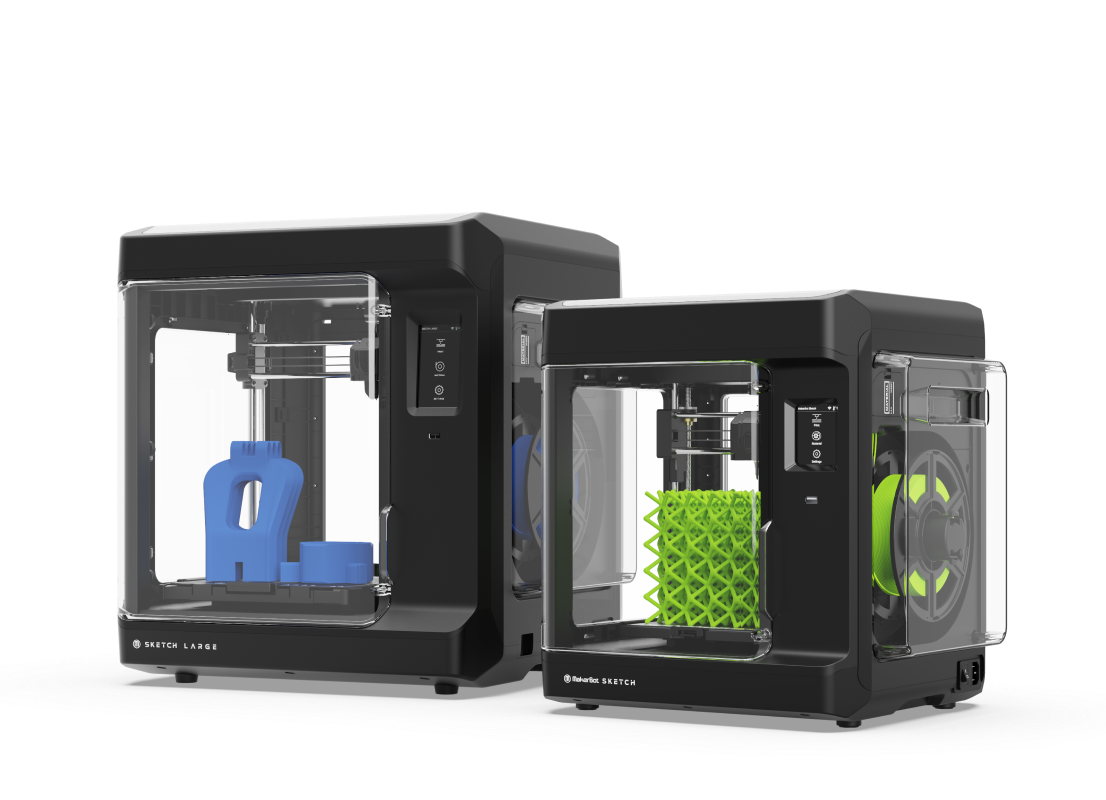

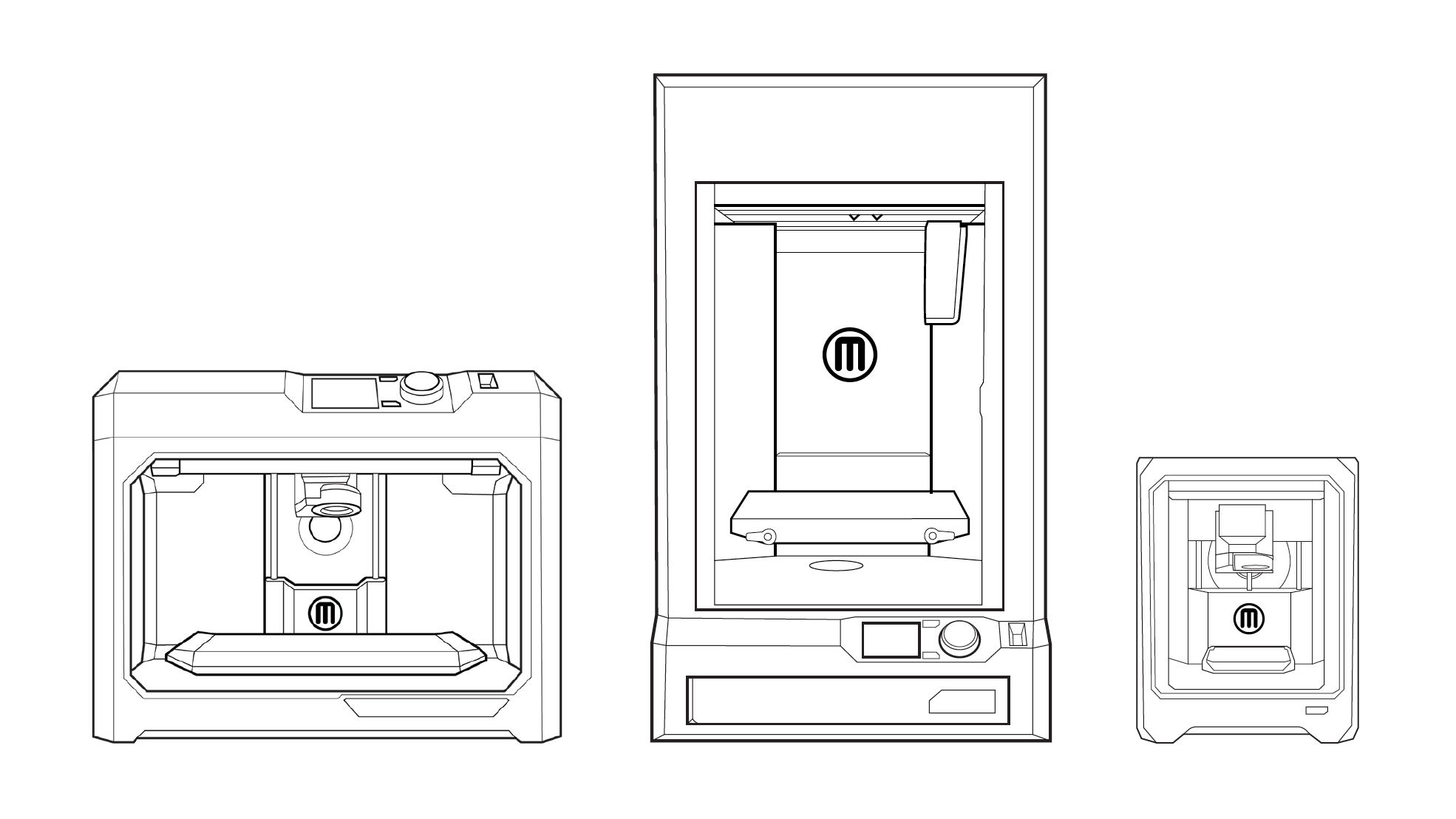

, after the expiration of a key patent on FDM technology, MakerBot launched and helped bring 3D printing technology into the mainstream. Building on the success of RepRap, MakerBot made open-source DIY kits for people wanting to build their own 3D printers or 3D printed products. The company also created the online file library, Thingiverse, which allowed users to submit and download 3D printable files. Thingiverse became the largest online 3D printing community and file repository in the world.

2011

The idea that 3D printing was only for small objects got turned on its head. The engineers at the U.K.’s University of Southhampton designed the world’s first unmanned 3D printed aircraft. The total cost came in under $7,000.

That same year, Kor Ecologic presented Urbee, a prototype car with a 3D printed body at the TEDx Winnipeg conference in Canada.

2013:

marked the year 3D printing became truly mainstream when the President of the United States, Barack Obama, during his 2013 State of the Union address, talked about 3D printing as having “the potential to revolutionize the way we make almost everything.”

2015

Swedish company Cellink made available for sale the first commercial bio-ink. Made from nanocellulose alginate, a material derived from seaweed, it can be used for printing tissue cartilage.

Cellink’s bio-ink cartridge sold for $99. That same year, it began marketing its INKREDIBLE 3D printer for $4,999. Because of these 2 products, 3D printing suddenly became more affordable for a wide range of researchers throughout the world.

2019

From 3D printed houses to and printing in space, to 3D printed living tissue, breakthroughs in 3D printers and 3D printing are happening faster than ever before. 3D printing is quickly expanding into diverse facets of our society such as manufacturing, medicine, education, aerospace, fine jewelry, and more.

3D printing has already demonstrated its massive impact and potential on our world. How that potential evolves in the future promises to change life as we know it.